Ελεγχος ποιότητας

QMS

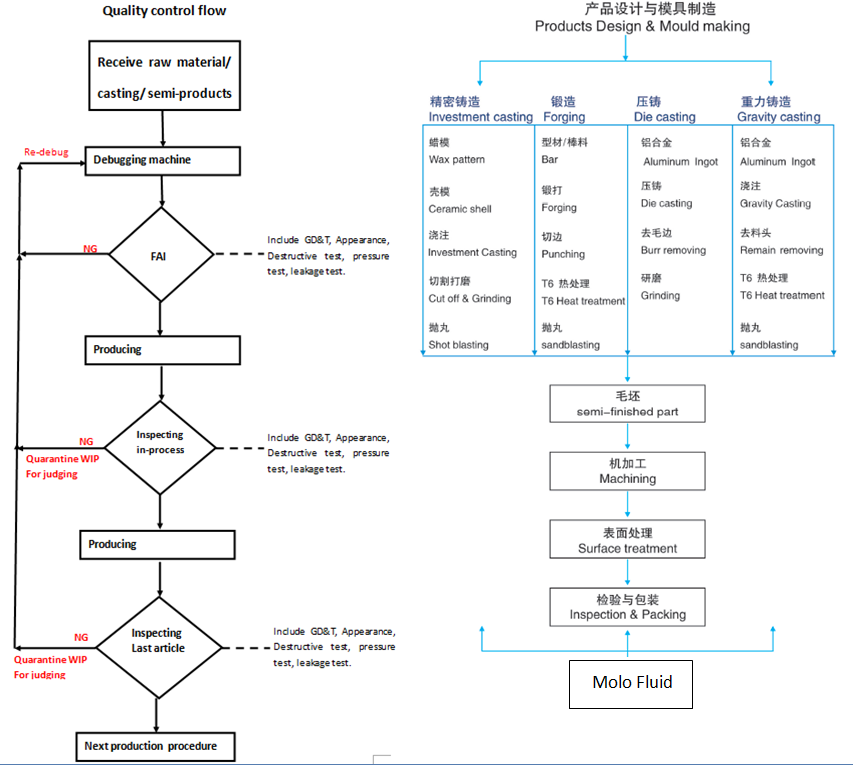

Molo Fluid set up complete QMS to control quality through verifying raw material, inspecting DG&T and Appearance , making testing on camlock coupling, Pipe fitting, hoses to meet customers’ requirement. Perform activities strictly and precisely to make sure products are high quality according to drawing and customers’ need.

Purchasing and incoming

Purchase raw materials directly from qualified factories which are qualified through audited and assessed on site.Verify raw material to make sure mechanical property enough.

Quality control in-process

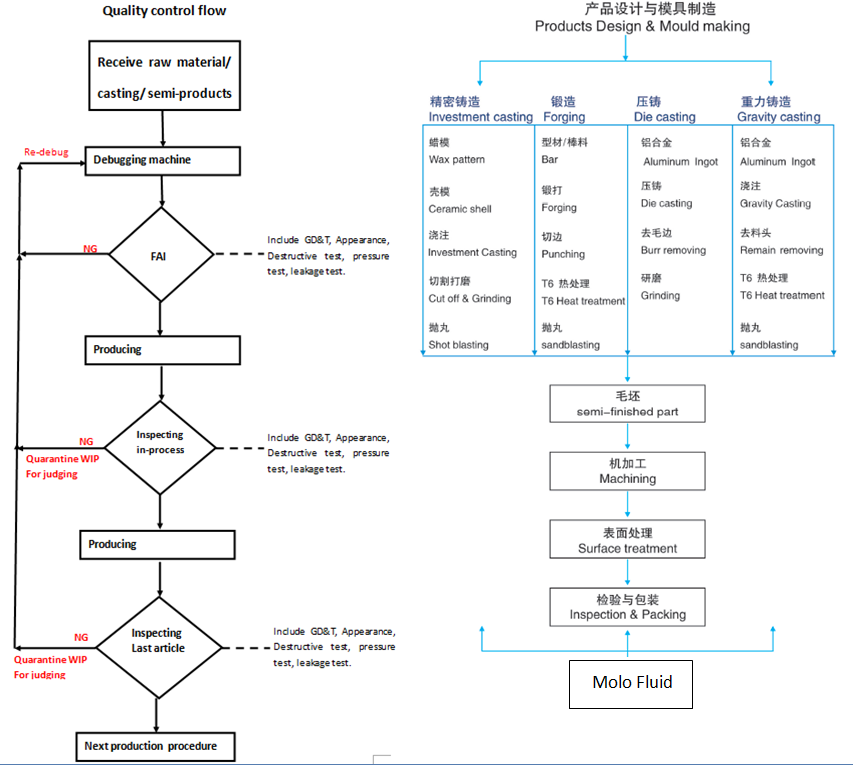

Aluminum camlock coupling is manufactured through die-casting or gravity casting and then to machine by CNC lathe.Brass hose coupling is through forging and machining.Stainless steel camlock coupling and pipe fitting are through precision casting and machining.Plastic camlock coupling is through injecting. Non-standard hardware parts are machined on CNC.Experienced engineers design 3D drawings, Quality control plans and production processes for camlock coupling, fittings, hoses etc. IPQC inspect semi-products for each manufacture process to control quality, confirm consistency between FAI and last article to make sure production process stably.

Shipment

According to Customers’ quality requirement and Drawings, qualified OQC inspect Camlock coupling, fitting, hoses and other goods with AQL. Confirm porosity inside of metal Camlock coupling through destructive test, make pressure testing and leakage testing to assure products qualified. Package goods according to SOP or Customers’ special requirement, Label each box and pallets with tag.All IQC, IPQC, OQC are qualified

.

Ελεγχος ποιότητας

QMS

Molo Fluid set up complete QMS to control quality through verifying raw material, inspecting DG&T and Appearance , making testing on camlock coupling, Pipe fitting, hoses to meet customers’ requirement. Perform activities strictly and precisely to make sure products are high quality according to drawing and customers’ need.

Purchasing and incoming

Purchase raw materials directly from qualified factories which are qualified through audited and assessed on site.Verify raw material to make sure mechanical property enough.

Quality control in-process

Aluminum camlock coupling is manufactured through die-casting or gravity casting and then to machine by CNC lathe.Brass hose coupling is through forging and machining.Stainless steel camlock coupling and pipe fitting are through precision casting and machining.Plastic camlock coupling is through injecting. Non-standard hardware parts are machined on CNC.Experienced engineers design 3D drawings, Quality control plans and production processes for camlock coupling, fittings, hoses etc. IPQC inspect semi-products for each manufacture process to control quality, confirm consistency between FAI and last article to make sure production process stably.

Shipment

According to Customers’ quality requirement and Drawings, qualified OQC inspect Camlock coupling, fitting, hoses and other goods with AQL. Confirm porosity inside of metal Camlock coupling through destructive test, make pressure testing and leakage testing to assure products qualified. Package goods according to SOP or Customers’ special requirement, Label each box and pallets with tag.All IQC, IPQC, OQC are qualified

.